One of the most frustrating aspects of drywall installation is the eventual minor damage to the finished surface, including cracking and screw pops. You can avoid some screw pops by understanding what makes drywall screws pop out?

There are several reasons you may see drywall screw pops immediately or eventually after the drywall has been installed for a while. This article will discuss environmental factors, workmanship issues, and other problems causing screw pops, how to prevent as many screw pops as possible, and how to repair areas that have been affected by popped screws.

What Causes Popping

The most common cause of screws popping are screws that have been sunk too deeply into the drywall surface. Drywall consists of a brittle, fragile layer of gypsum dust sandwiched by layers of paper-like material. The paper is what gives drywall its strength.

When you attach drywall, screws should be countersunk to the exact depth. Too high, and the screws sit too far up and are hard to mud and tape over. These don’t usually cause pops – they can be heard by scraping a drywall knife over the surface of the drywall and listening for the screws to catch on the blade – but they should be fixed before finishing the drywall. If screws are sunk too deep, they will rip through the paper and no longer be holding the drywall tight against the frame. These screws are held in place by the stud, but the drywall is free to move around the screw. When the drywall contracts or expands, it causes the drywall to break away from the joint compound, the drywall surface, and leaves visible circles in the paint.

Another common reason your house might experience screw pops is wide fluctuations in moisture, humidity, or temperature. This often happens when homes are drywalled without airconditioning. When the drywall is suddenly in a climate-controlled environment, it expands and contracts, causing the drywall to pull at the screws holding the panels onto the frame. These screws stay in place, and the drywall moves around them with the temperature fluctuations.

It’s also possible the wood framing was holding onto a lot of moisture before drywall installation. The wood contracts, the drywall absorbs some of the moisture, and everything shifts.

Other Issues

Believe it or not, you can have too many screws. The more screws you install, the more likely you’ll get at least one badly sunk screw that will end up popping. Your average DIY drywall project will use 4 x 8-foot drywall panels. These panels should have at least 32 screws per panel when hung on walls and 36 screws when hung on ceilings. Always check your local building codes to ensure you’re putting enough attachments in each panel.

Your screws are too long. Screws should penetrate at least 5/8 inch into studs. That means standard 1/2 inch drywall or 5/8 inch drywall should be attached with 11/4-inch screws. Screws that are significantly longer are harder to drive in straight. When the drywall contracts, it puts more angular pressure on the screws, causing the longer screws to pop more frequently.

Too much glue. Glue, especially latex adhesives, shrink while they dry. If there is a lot of glue between the wood studs and layer of drywall, it could cause a significant pull as it dries, popping screws near the adhesive blobs.

Lightweight drywall. Some types of drywall are more prone to screw pops. Lightweight drywall typically has lots of holes or bubbles that make them lightweight but don’t hold screws as well and sit looser on the walls. Loose drywall moves more, causing more screw pops. The paper also tears more easily, meaning if you’re not careful, you’ll have screws popping right away if you don’t back out the screws or add screws to compensate.

How To Prevent Screw Pops

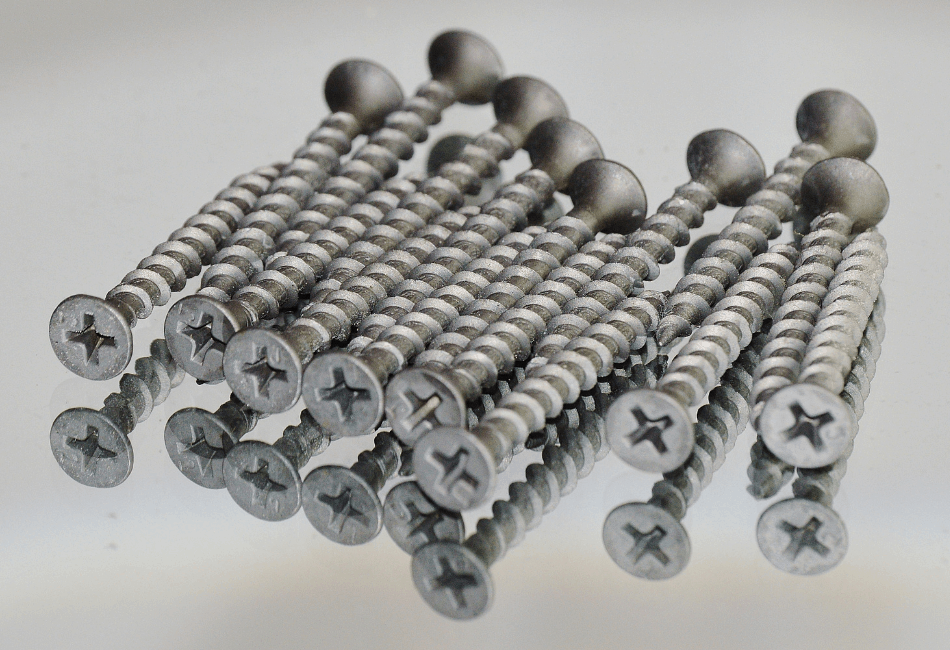

Choose the right drywall fasteners. Since drywall nail pops are more common than screws popping, if you want the best chance at avoiding pops, use appropriate drywall screws. Use screws that are 5/8-inch longer than the thickness of the drywall. The most common screws are #6 1 1/4-inch drywall screws. Longer screws will be harder to drive straight, and angled screws are more likely to pop. Use bugle head self-tapping screws to get a good countersink that won’t damage the paper.

Sink screws correctly. Probably the most important aspect of avoiding screw pops. The screw heads should just dimple the drywall paper. Most drywall contractors and professionals use a drywall screw gun for perfect sinks. These specialty tools have nose cones that prevent the tool from driving screws past a certain depth. You can achieve similar results with a power drill or impact driver and a drywall screw setter.

Related: Best drywall screw setter review.

It’s important to at least have one of these dimplers to set your screws properly. Go as slow as you need to get straight, perfect depth screws.

Let your drywall adjust to the room. Like with a hardwood floor, it’s a good idea to let your drywall adjust to the temperature and moisture content of the room before you hang it. Let the drywall spend a day in the environment you’re going to install it in. This prevents wild shifts and contractions in the drywall that cause drywall movement against the frame and screw pops.

Test the moisture of your frame. Get a moisture meter and test your frame before you install drywall. If the relative moisture in the frame is significantly high, give the frame time to adjust to the humidity. Wood movement is a major cause of drywall screw pops.

Apply adhesive lightly. Instead of big gobs of drywall adhesive, apply it in a thin bead along the wood studs. If you are using it only in certain spots, screw around the adhesive instead of into it. This allows the adhesive to dry and contract without pulling directly on the drywall attached around the screw.

Control the temperature in the house. Screw pops, drywall cracks, and other issues tend to crop up in vacation homes and houses that are left empty for long periods. Drywall that experiences temperature extremes or goes from a humid environment to a dry environment will expand and contract, causing not only screw pops but also cracking.

Related: Best drywall screws review.

Repairing Screw Pops

A few screw pops is usually nothing to be concerned about, but they don’t look great on your smooth, finished walls. You can’t just paint or mud over a drywall screw pop- the panel will continue to move and just pop right through the coat of paint. Repair is fairly easy, though you’ll need:

- Drywall Screws

- Drywall Screw Setter and Powerdrill

- Drywall Compound

- 120-grit Sandpaper

- Paint

You could also get an all-in-one drywall patch kit that has everything you need for drywall repair minus the screwdriver.

The first repair step is to add two fasteners for every screw pop—one above and one below the screw that has popped. Add a thin layer of mud over the screws, allow it to dry, then sand the area smooth. Finish with paint.

Drywall screw pops are easy to fix and easy to avoid if you’re careful when installing your drywall. Use the correct type of fastener – 1 1/4 inch coarse thread drywall screws for most projects, and have the right tools to correctly sink each screw to the right depth. Either use a drywall screw gun or a drywall screw setter on your cordless drill. Prep your drywall and take your time attaching it, and you can avoid screw pops altogether.